MG-Cars.com

Triumph TR3 Vapor Lock -What is it? BBS discussion at MG-Cars.net

MG-Cars.net

Welcome to our resource for MG Car Information.

Recommendations

Parts

TR parts and Triumph parts, TR bits, Triumph Car Spares and accessories are available for TR2, TR3, TR3A, TR4, TR4A, TR5, TR6, TR7, TR8, Spitfire and Stag and other TR models are available from British car spares and parts company LBCarCo.

Triumph TR3 - Vapor Lock -What is it?

| My friend is having what he calls Vapor Lock. What is it exactly. We have set up his car identical to mine and his has these incidents of stalling out and then running fine. We have changed out everything except the check valves in the fuel pump. Any thoughts from the gurus? |

| R.L. GANNON |

| I'm no guru, but vapor lock is boiling fuel somewhere. Probably in the float bowls or fuel lines close to the head. There's a guy in Iowa that makes heat shields and some other cool stuff for our cars. I've seen them on ebay. IF your cars are setup close to the same, maybe his is richer to start with. Or maybe leaner, I dunno. But it seems like they run too rich when they're hot. My brain hurts. You're lucky if you don't ever have hot fuel problems. It seems like most people do. Fuel injected cars have less problem with this, as (like cooling systems) they're under pressure. And liquids under pressure boil at higher temps. I've always had stuttering in hot weather after a heat soak (parked for a while after getting up to full running temp). They start kinda hard and then when the cooler gas comes in, it gets better. I believe it's fuel boiling in the float bowls, and radiant heat from the exhaust manifold can be extreme. I've heard of guys pouring water on the float bowls to cool them down enough to start (if you don't want to just wait). Maybe a spray bottle of water could get you going pretty quick. It's the season! Thanks for making me think, maybe I'll carry a spray bottle now. |

| Tom |

| A word of warning on those heat shields. Some of them have to be cut in orderto clear the throttle linkage, so, before you torque down the carb bolts, check that the linkage has full range of motion. Since the heat shields are aluminum, the Dremel or sinilar tool is usually adequate for the job. Al Christopher |

| A R Christopher |

I suspect that my problems started while driveng to VTR where the gasoline in USA has 10% or more ethanol added. Ethanol is more volatile. It happened about 6 times, usually when 2 lases of traffic about 3 miles long had to merge into one lane because of road construction. I turned on my electraic fan and this prevented the engine cooant from overheating, but when I get by the traffic and get moving again, it would sputter like it was running on 2 cylinders. It happened again last weekend when I filled with Sunoco which I was told has ethanol in it. So does Petro-Can. Esso and Shell is what I normally use and these seem to work fine here in Canada.

|

| Don Elliott |

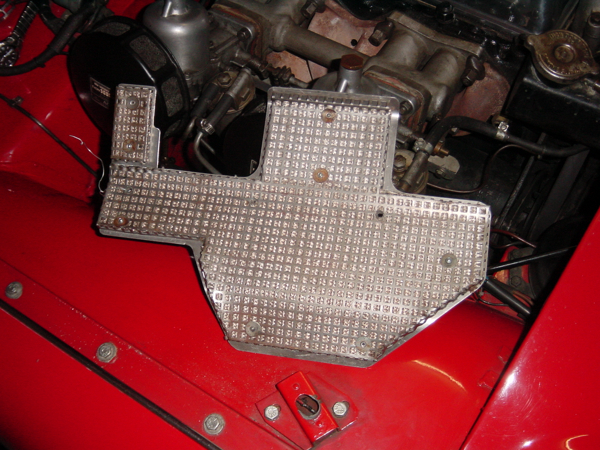

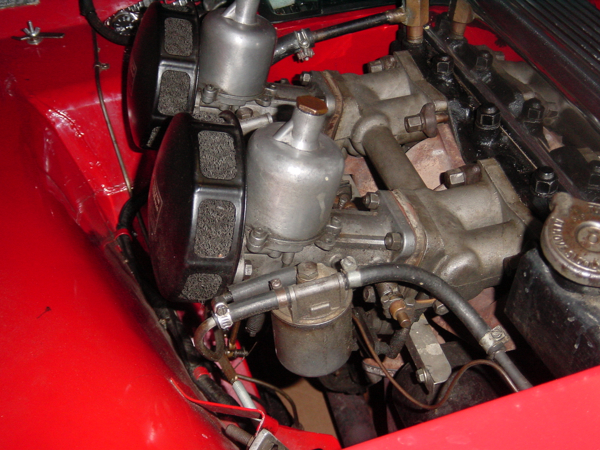

| I had this problems a few years back and I fabricated a screen that reduces the heat radiation from the exhaust manifold. I cut the screen in a 1mm thick aluminum sheet and shaped it to accommodate everything around, Then I captured a heat insulation material between the aluminum screen and a doubler perforated plate (see picture), and used blind rivets to keep everything together. The screen is secured (3 screws) to an aluminum angle bolted underneath the intake manifold (on existing studs) providing a firm bracket to support the screen. My screen has proved efficient, and I remove it in the winter when it is not needed. The screen is removable without dismantling anything else that the 3 securing screws. I have more pictures but it allow to load only one at a time. If anyone wants more details I can send a couple more pictures.  |

| Jean Louis Lafont |

| Nice. |

| Tom |

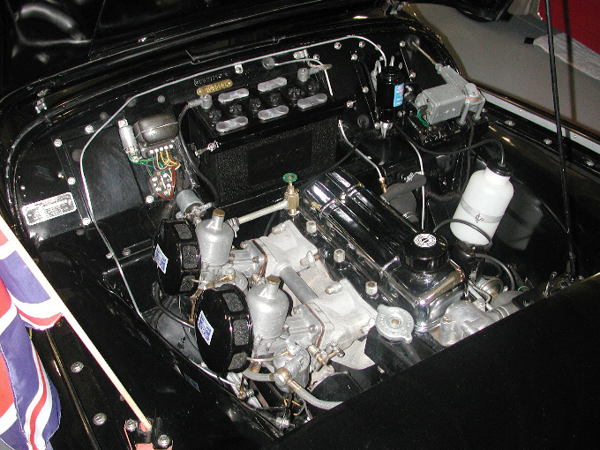

| Jean Louis - Merci pour l'idee. I thought of that. But I want to keep my car looking "original". Some are available in USA but they cannot be easily removed for a concours show. How are yours removed ? Is it quick and easy to remove yours ? I have 49 year old fuel hoses to my SU Carbs and maybe the ethanol causes to rubber to swell. You can see these in the image above - leading to the banjo fittings which are correct for my car (TS 27489 LO). I will try to find modern hose rubber that would resist the newer fuels and keep the old fuel hoses to install only for concours shows. Don Elliott, Original Owner, 1958 TR3A |

| Don Elliott |

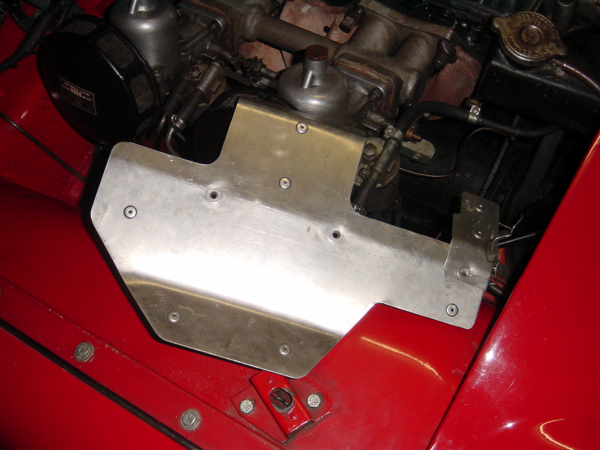

| Bonsoir Don - The screen can be removed in 5 minutes, it is a tight fit, and it is safe to disconnect the battery in case that by inadvertance, during the removal of the screen, the negative connection on the starter is touched with the aluminum screen. but with some practice, as I said, 5 minutes is okay without removing anything else. However, the rail to which the screen is bolted to, stays there, it would take I guess another 5 minutes or more to remove it. This rail, an aluminum angle profile 15mmx15mmx2mm thick, (sorry 9/16x9/16x3/32 thick), is secured to the 2 studs that are bolted into the inlet manifold and go through the exhaust manifold, to keep them firm together. I use these same original studs to secure my aluminum rail together with the manifolds. You can see it (the rail)on the picture. Also the screen is in 2 parts, a small addition forward, over the throttle linkage. I attach 1 picture showing the outer face of the screen (carbs side), the previous picture was exhaust manifold side. I will make another message with a picture showing the rail.  |

| Jean Louis Lafont |

| Don, this picture is another view of the rail (front) secured below the manifolds, using the original studs that keep them together. As you can see, my engine bay is not "concours" but my car runs well. I do what needs to be done but avoid to start large projects (maybe when I retire). We had exchanged a few comments when I rebuilt my gearbox and OD 3 years ago. This is now done and working fine. I had also asked a question about the axle hubs removal, and a gentleman (forgot the name now, I would have to seach the archive) had given me the precious advise to remove the half shafts and do the job with a press, rather than fabricating a puller. Well, I did that, and it worked excellent. I had to apply 20 tons to pop them off, and I realised how much I would have suffered with a puller. I saw however, on the TR6 BB a guy made a very nice and sturdy puller. Okay, I am mixing the subjects here. Sorry. BTW, I do not have a picture with the screen installed, and I am away of my car at the moment, but I will post one in a couple of weeks when I return.  |

| Jean Louis Lafont |

| Merci encore une fois Jean-Louis. Where are you located in France. I have been many times to France, mainly Lyon, Provence but also Bretagne, and Normandie. I will look for the photo. |

| Don Elliott |

| Don, I live in a village nearby Toulouse, SW. I work in Brazil and I am commuting. I am in France 6 months in the year. I forgot to mention, I used "captured" nuts on the rail, so when installing the screen, no need to bother for the nuts, they are there, captured on the rail. They are these square nuts captured in a cage that clips on square holes. |

| Jean Louis Lafont |

| Jean-Louis - When you get back to France, you can send the photos to my e-mail address. 58tr3a "AT" videotron "DOT" com Merci Don |

| Don Elliott |

| I just thought of maybe insulating the float bowls somehow. Like a couple layers of fiberglass cloth, then some heavy aluminum foil over that. Wired on? Just a thought, definitely not concours, but easily removable and cheap. |

| Tom |

| As a follow up and progress report, Bill is going to take the following steps and then let me know. 1) At locations where there might be a possible impact of ehaust heat under the car, those areas which are close, will be insulated. 2)In the engine bay, the entire fuel line will be insulated. There exists a previously installed heat shield from ARE. A solid stainless steel unit, which is already taking effect on the carbs by blocking the heat from the exhaust manifold. Question to all you folks of great wisdom: Would those chromed piston pot covers help deflect heat from the carbs or is it a mute point at that juncture? |

| Robert |

| Jean-Louis: Your ancient fuel hoses might be the entire problem, since some of the old hoses swell up badly, closing or nearly closing the lumen of the hose, and starving the engine of fuel. Al Christopher |

| A R Christopher |

| Al, I do not have a problem with fuel hoses, I just joined this thread to try to help. I had problems 4 years ago with the heat radiated by the exhaust manifold (vapor lock) and I solved them with the screen I described in the above comments. But I agree with you, old hoses can become a problem, in various forms. Years ago, I found the hose between the tank and the rigid pipe (below the rear the car) was covered with an emulsion of gasoline, like if it was white frozen. Needless to say, my garage had been smelling gas for months before, and closing the fuel tap didn't help. There was a good reason to this! Don, Will send pictures of the mounted screen and details to your email address. This will be after the 22nd of this month. |

| Jean Louis Lafont |

| Several TR owners are complaining about problems because of the ethanol which is added to the gasoline. Problems with the protective coating inside gas tanks, inside old rubber hoses, vapour lock where the fuel leaves the lines dry or with a vapour which obstructs the gas flow, so the float bowls become empty and then you get the feeling that you have run out of gas - which you did. |

| Don Elliott |

| Don, the mails I send to your address you indicated above, return as "undelivered". Please write me and I will return with the shield drawing and pictures. my email: jllafont@wanadoo.fr |

| Jean Louis Lafont |

| Hi guy's, Another little trick is to pull out your choke for a few seconds when it starts to occur. This allow the influx of cooler gas to rapidly enter the float boals were the gas is boiling and causing the problem. |

| WMR Bill |

| Special thanks to R. Gannon for his help. I am the friend with vapor lock problems. A new finding and added twist. Original fuel tanks apparently have a steel tube running the length on the fuel tank on the INSIDE. This tube connects to the vent tube at the brass fitting on the top of the tank. It's purpose is to vent the tank with out allowing fuel to slosh out. My car was retored in 1992. The restorer slushed the tank with sealer. Unfortunately, the end of the vent tube was filled with a 3/8 inch plug of this rubber sealer. Therefore, my tank only vented through the pin hole diaphram vent in the gas cap which caused a vacuum, and either starved the engine on cool days or (I think) vapor locked on hot days when very little fuel passes through the supply tube running from the pump to the carbs. I did install the carb heat schield which has worked very well. How did I find and repair the problem? Removed the tank from the car, used a mirror to inspect the inside of the tank looking for dirt. Found the tube, recognized the problem and cut a small hole in the side of the tank to find the end of the vent tube. I then used a 1/8 drill bit to screw into the plug and pulled it out. Compresses air would not blow it out. Then patched the hole in the tank. I hope to be back on the road in a few days and will see how well the car performs with an unobstructed flow of fuel. One question? I saw several TR-3s and TR-4s a few weeks ago at a show. Half had 5/16 inch steel fuel tube running from the fuel pump to the carbs and the other half had a smaller 1/4 inch tube. Which is correct? My car has the larger 5/16 tube. Would the smaller tube contribute to or reduce the problem of vapor lock?? Again, thanks to all and especially Robert for his continued encouragement. |

| W R E William |

This thread was discussed between 26/07/2007 and 24/08/2007

Triumph TR3 index