MG-Cars.com

Triumph TR6 Flywheel BBS discussion at MG-Cars.net

MG-Cars.net

Welcome to our resource for MG Car Information.

Recommendations

Parts

TR parts and Triumph parts, TR bits, Triumph Car Spares and accessories are available for TR2, TR3, TR3A, TR4, TR4A, TR5, TR6, TR7, TR8, Spitfire and Stag and other TR models are available from British car spares and parts company LBCarCo.

Triumph TR6 - Flywheel

| Ok Folks So I got one broken clutch to flywheel bolt out (used a helicoil to replace damaged threads etc), I cant get the second one out, as I broke a small drill bit and thats stuck in there and I have gone through a number of titanion bits try to drill through it. So now it may be easier to remove the flywheel and take it to a machine shop. So my friends any tips on removing the flywheel would be appreciated. BOB Evans, Im back in town after Thanksgiving. I will call you when Im in. Les Oh, Happy Thanksgiving to the folks in Canada and USA. Happy Harvest Festival to all my Commonwealth Cousins. |

| lw gilholme |

| Les, Post a pic of you problem |

| DNK Don Kelly |

| For removal I would normally just grab a 1/2" impact wrench along with the appropriate socket for the flywheel bolts (six point for the stock type bolt, twelve point for ARP bolts) and remove the four bolts that hold the flywheel to the crankshaft. After that, the flywheel gets "pulled" although I found this often involves needing to rock it part way off using a small prybar. If you don't have ready access to a 1/2" impact you may need to fabricate a small holding fixture to prevent the crankshaft from rotating as you remove the flywheel bolts. There are many options on exactly how to make the holding block, the main thing is that you have a way to either bolt or clamp it to the adapter plate while have point(s) that fit in the valleys of the ring gear teeth in order to keep the crankshaft from rotating. |

| SteveP1 |

| Yo Les: Good to hear from you again. I am off on the annual Moose hunt Friday to Sunday so will be giving up the Thanksgiving turkey, hopefully, for the Thanksgiving Moose. The interior is back in the TR6 and just clearing up some wiring and coolant hoses for the startup. Come by the garage when you're free. Fridge is stocked. Cheers, Bob |

| Bob Evans |

| Les, Aerokroil, liberally applied successively will solve your problem... http://www.kanolabs.com/ db |

| Doug Baker |

| Well folks, all good advice. After what seemed an age and many drill bits, I managed to drill out the old bolt, so I tapped for the new helicoil, and yes I used oil to help it. Just had one last 1/2 turn then the tap snapped....aaaaaaaaaaaaaaaaaaaaaaahhhhhhhhhhhhhhh. In the end I took the flywheel off..no problem there just wish I had done it earlier...now its Friday of Thanksgiving...im hoping that the machine shop can do get the tap out and put the helicoil in....if not I have to work on the woman cave....I know what I would rather be doing..Cheers have a good weekend.. Oh Bob...good idea "Save a Turkey this year. Bag a Moose instead. Lots of moose up here.... Les |

| lw gilholme |

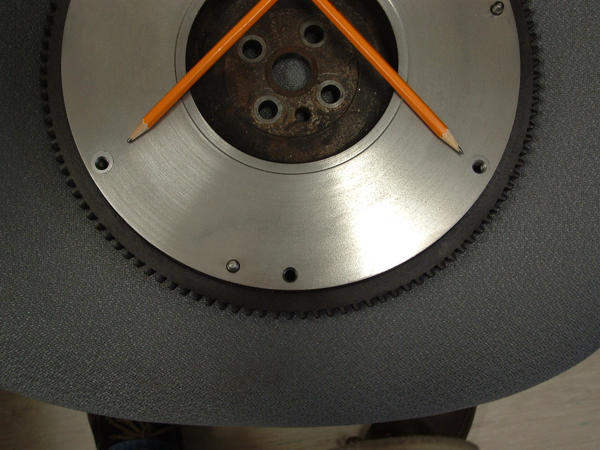

| Well its Friday. The fly wheel came back today, they pluggged, drilled and tapped my errors. oh they also cleaned the face. So clutch is going in on Saturday. See the pics of the flywheel, the pencils point to the repairs. Les  |

| lw gilholme |

| Nothing that a little money and time won't fix eh Les. I had a few of those when I did my car. |

| Michael Petryschuk |

| Mike, you so right, all the time spent trying to sort it out....well its on the car now, and so is the clutch and gear box....today was so good that I put the exhaust on just for a fit test. Les |

| lw gilholme |

This thread was discussed between 08/10/2013 and 27/10/2013

Triumph TR6 index