MG-Cars.com

Triumph TR6 Rear Side Axles - Are We Safe? BBS discussion at MG-Cars.net

MG-Cars.net

Welcome to our resource for MG Car Information.

Recommendations

Parts

TR parts and Triumph parts, TR bits, Triumph Car Spares and accessories are available for TR2, TR3, TR3A, TR4, TR4A, TR5, TR6, TR7, TR8, Spitfire and Stag and other TR models are available from British car spares and parts company LBCarCo.

Triumph TR6 - Rear Side Axles - Are We Safe?

| G'Day Mates: Recent posts and other info I have read gives me cause for concern over the 36 year old side axles in my '76 TR6. We've all heard stories about catastrophic failure from metal fatigue but thankfully no horror stories of serious injury or worse. Maybe it's just a matter of time though. What is the consensus out there? Should we all be replacing the outer side axles at $160 apiece (from latest Moss catalog) or upgrading to complete, strengthened hub units or CV assemblies from Goodparts or similar replacements? Is magnafluxing a suitable diagnostic check or could catastrophic failure occur spontaneously with no prior warning and nothing showing up on the magnaflux scan? I had never really given a great deal of thought to this but I have replaced or refurbished nearly every moveable part on my car, including road wheels for just that reason (age and load bearing stresses) and I guess getting older one wants to simply continue getting older as it sure as hell beats the alternative. I have spent a small fortune on the TR6 and a few more $$ will not likely be a problem but I'm curious to hear other opinions on this issue. Hoping for a good response, which would really be a help to all members. Care to start off Steve - your posts are always thoughtful and well received? Cheers, Bob |

| Bob Evans |

| I don't know about always thoughtful and well received, I can think of some exceptions... Are we safe is kind of a loaded question in that there are lots of "it depends" that need to go along with any answer. In general, I think most would be safe for the typical use these cars see now. If in the past there was some abuse/not properly performed repair work or some out of the ordinary environmental exposures, then there is some additional risk involved and face it, how many of us know the full history of their particular TR-6 these days. But again, in general, I think most would be OK. From a non-destructive inspection standpoint, magnetic particle inspection or liquid penetrant inspection should be a reasonable means of checking a part out while things are apart before reassembly and putting it back into service. Can something happen anyway even after NDI? Sure, there's always the possibility of a missed indication but if you're dealing with a competent inspector those odds are pretty low. Now on the anal retentive and nutcases out there (hey, I resemble those remarks), if you have modified the car, really push it around as you try to drive the wheels of it, etceteras and so on, it is something worth considering. For example, todays rubber is orders of magnitude better than what was available when these cars were new and if you have bumped up the tire size and drive it hard, you're putting loads into the car that probably were not anticipated by the designers. For these folks, going to something better makes sense. Have I done so? No, I just haven't been ready to pull the trigger on that yet, but I keep coming back to it. It's only a matter of time until I do. I keep coming back to watching a rear stub failure on a TR-250 at a VTR National Convention during the autocross event. It was not a pretty sight. |

| SteveP1 |

| A person from the 6pack forum has sent me 9 photos of broken axles that he collected from various sites. What is the easiest way to post them here? Berry-computer Neanderthal |

| BTP Price |

| A couple of different ways, first is to hit the upload link at the bottom of the comment posting area. You would only be able to hit one image at a time going that route. I have also done a "cut and paste" into something like PowerPoint then did a "save as" to a JPEG image format for multiple pictures to save them as single "image." Either way you have to watch the file size as there is a limit to the max file size for images that you upload. I think the highest number of pictures that I turned into a single image and got it to upload is three and even then I had to do some compressing or resizing of the images plus play with the resolution. The test case loaded here is just over 100kb and it loaded with no problem. Since it is copyright material, let's give credit where credit is due, this is from "Get Fuzzy" dated 24 May, 2012 off the Houston Chronicle website. Since it's Triumph related and used as a demonstration example with due credit given, that should constitute fair use. Mike, if you think otherwise, delete the attachment and add a note that it was deleted.  |

| SteveP1 |

| Steve-Is there anyway to forward the email I recevied with the pics&links to this site? I was wrong, there are more than 9. I will show my email, if you want, I can send them to you. Berry btp44@aol.com |

| BTP Price |

| Bob, A few years back, I was having issues with the sliding splines, and right after I bit my lip, I pushed the order button and picked up RG's CV joint axles and uprated hub assemblies. Not too long after that, I found the "uprated" axles from Moss. Tho I have not experienced the problems since the purchase, it was a bit of overkill, and if I had it to do over again, I would probably get his hubs, and do the uprated axles. I have put about 40,000 miles on my car since 2003, and the axles themselves didn't really worry me as a possible failure. Hubs? Maybe....but I never really wanted to put the car in an autocross or hillclimb, just cuz I know what happens if you keep doing that sort of thing. Parts will break, and I would rather take long trips to other parts of the country in this car than autocross. I almost changed my mind at the Triumphest, 2004, at Lake Tahoe, then I thought about the 500+ miles back to Boise. Turns out it was a good decision, I racked the car at work for an oil change after the trip and found the nylocs on the diff /axle flanges had loosened, and the stress of running that autocross course woulda been bad. Wife would have killed me. She told me that. So, since I already made the short story long, unless you plan to throw the car into some speed events, I wouldn't be too worried about the axles. These are sports cars, and they will get thrown into a corner aggessively once in a while, I think just keep it maintained, upgrade and/or fix what you need to, and drive the d*** thing! Rod |

| Rod Nichols |

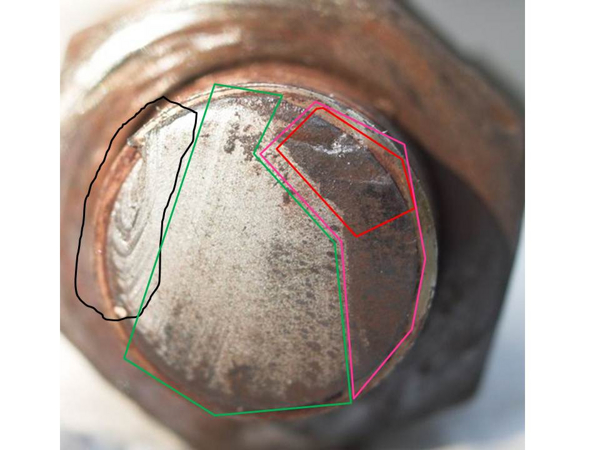

| Have some stuff from Berry, first the easy stuff, some URLs related to broken axles: http://www.tr-register.co.uk/forums/index.php?showtopic=7844&pid=50579&mode=threaded&start=#entry50579 http://www.kolumbus.fi/triumph.tr6pi/broken.htm http://www.british-cars.org/triumph-tr6-bbs/rear-stub-axel-200907200107016240.htm http://www.britishcarforum.com/bcforum/ubbthreads.php/ubb/showflat/Number/602387/Searchpage/7/Main/61077/Words/+hub+%2Bfailure/Search/true/Re_TR6_Axle_Shaft_Failure_Revi#Post602387http://www.britishcarforum.com/bcforum/ubbthreads.php/ubb/showflat/Number/602387/Searchpage/7/Main/61077/Words/+hub+%2Bfailure/Search/true/Re_TR6_Axle_Shaft_Failure_Revi#Post602387 hmmm, some of those names seen have a familiar ring to them... Now for a composite of some breaks, see the image. Note what they have in common other than that they are broken.  |

| SteveP1 |

| Seems to be hub failures....not the axle shafts.... |

| Rod Nichols |

| Now lets look at one of these in more detail. We appear to have a tensile loading fatigue failure with a fair amount of corrosion as a potential factor. The failures all seem to start at the root of the thread on the stub axle shaft. In the pink box we have an area that has been broken for some time with the worst of it in the red box. Also note in the red box that you have a couple of ares that show evidence of rapid crack growth that was arrested before it had a chance to go critical. Moving to the green box, we have a series of striations that go from very fine to somewhat coarser moving from right to left indicating a pick up in speed of the crack growth rate. Finally in the black box, we've gone critical with the striations shifting out of being relatively straight lines and becoming much coarser, even leaving what appears to be a bit of a tang at one end from what looks to be a thread major diameter. We don't really have enough detail in the pictures to see it, but I bet if we did, that area in the black box would have a relatively "grainy looking" surface inside those elipses when it finally let go. So what does it all mean Mr. Natural? (sorry, too many underground comics in my past) I think it still comes down to service history, environment and that "it depends" mentioned earlier. All of these pictured showed a good bit of corrosion in the hub area and/or on the stub axle itself in some of the other shots. Given all of this, here is what I would suggest: 1) If yours look all rusty and crusty, be suspicious. 2) Only let someone with the proper tools and that knows what they are doing take apart your hub assemblies. 3) When they are apart, have them inspected by something more than just a visual inspection paying particular attention to the thread roots and have it done by a competent NDI person, ASNT Level II or III over here, whatever the standard is in your neck of the wood if you are somewhere else. And when in doubt, throw it out. 4) For reassembly, again, it needs to go to someone that knows what they are doing and doesn't just run the nut on until the impact gun chokes. They need to know how to properly set up the end float and it's not by running the nut on until the impact gun chokes as I have seen a couple of people try and do. 5) And if all that sounds like too much trouble, call Richard Good or Racestorations or Kevin Yatani or Moss or Revington, etc. It's like the philosopher Homer Simpson said one time "money can be exchanged for goods and services."  |

| SteveP1 |

| From the adverse information files, found this for those that might have wondered about the Mr. Natural bit, the cover of R Crumb's Mr. Natural, Issue 2. damned hippies....  |

| SteveP1 |

| I was sorry to see this thread go dormant. I have managed to glean 9 (I am sure there must be more) first hand accounts of broken axles from the info that Bob Danielson (6pack forum) forwarded to me and Steve was kind enough to post. Also, a couple from other sources. It was kind of like counting chickens, because some of the pictures and stories were duplicated. Some of the hubs had been rebuilt, some not. So, there is no clear evidence that the axles were damaged during the rebuilt process or not. Steve mentioned "tensile loading fatigue failure". Does this mean damage from tightening or over tightening the nut, possibly with an impact wrench? Did corrosion develop after the start of the crack? Could the manner in which the threads were generated be a factor-rolled vs cut? Anyway, whatever the cause, though the number of failures are relatively few, a broken axle or even the thought of it, is enough to ruin your day. Berry |

| BTP Price |

| I suspect the stub shaft breaking at the threads if the hub has too much end float. This would put more pressure on the shaft as the bearings would not offer as much support. As well end play would cause some "wobble" and the failure would be in the weakest area- the smallest diameter of the shaft and at the threads. tightening the stub shaft nut too much might put too much tensile stress on the shaft but I believe the nut threads might strip before it damages the shaft. |

| Michael Petryschuk |

| It's hard to say just by going from the pictures if this was a case of stress corrosion cracking or just your "normal" fatigue failure but my money would be on "normal." The reason that we see corrosion for part of the surface and decreasing amounts as we follow the failure across is based on the relative amount of contact between the two surfaces over time. The area where the crack started will typically show the most corrosion since it is where it has been open to the elements and been effectively out of contact the longest. When we go across the corrosion decreases due to two things. First is the reduced amount of time where it has been open to the elements, the second is that the relative motion of the two surfaces rubbing against each other knocks the corrosion down, sort of self polishing if you will. Eventually the area available to carry the stress is reduced to the point where the the crack grows rapidly and that takes you to last phase which is a tensile failure under these load conditions. It may sound a bit odd, but in a way I was kind of impressed. It's pretty obvious that this had been cracked for reasonably long time and that the final tensile failure area was relatively small. This would nominally indicate that the material is a relatively high strength steel but has pretty decent fracture toughness. Short of the more exotic high alloy steels like AF1410 or Aermet 100, there is a significant drop off in fracture toughness as strength goes up. In other words, once a crack starts, it propogates rather rapidly in low fracture toughness materials. Somebody did a good balancing act between strength and toughness when they called out the alloy and heat treat. |

| SteveP1 |

This thread was discussed between 25/05/2012 and 02/06/2012

Triumph TR6 index