MG-Cars.com

Triumph TR6 Too much play in throttle linkage? BBS discussion at MG-Cars.net

MG-Cars.net

Welcome to our resource for MG Car Information.

Recommendations

Parts

TR parts and Triumph parts, TR bits, Triumph Car Spares and accessories are available for TR2, TR3, TR3A, TR4, TR4A, TR5, TR6, TR7, TR8, Spitfire and Stag and other TR models are available from British car spares and parts company LBCarCo.

Triumph TR6 - Too much play in throttle linkage?

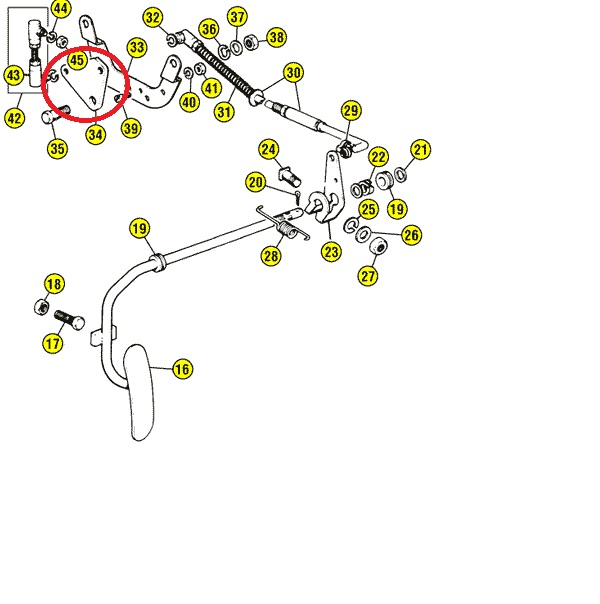

| Hi everyone, long time reader... first time poster. My question is how much play is normal in the bell crank lever? (I've circled it in the attached picture). When I press the accelerator I see a fair amount of movement from side to side before it starts to rotate. Thanks a lot, Mike  |

| MV Van Duzee |

| I think that that triangular bracket, item number 34 you've circled should be firmly attached to the arm, item number 33. If it's wiggling upon activation, perhaps the connectors are loose, though I assume that you checked those before posting. Check again. Maybe replace screws. db |

| Doug Baker |

| Everything is tight, I'm guessing that either the triangle bracket (34) or the bolt (35) is a little worn out. Thanks for the quick reply. mike |

| MV Van Duzee |

| Hi Mike, Everyone eventually needs a little help. Welcome. Actually Doug 34 rotates on the shouldered bolt (35) through the bottom hole of 34 with 43 attached to top left hole (of 34) and 32 attached to the top right hole. Both these 2 joints are a ball and socket joint. Bolt 35 should be tight with 36,37, and 38. There are more areas that I think are more likely to give you your "play" Keep in mind, this entire linkage should have a little play. #s 43 and 44 are both adjustable ball and socket joints. These 2 could be loose and may require lubrication. They can be disassembled and greased then re tightened with the slotted screw at the socket (it is not a screw as you would think of but describes it close enough). From Ball link #44 on, is to the throttle linkage. This area can have a lot of excess "play". The clamps on the front and back throttle spindles have to have a specific amount of play. Too much and it looks like you would put down half the foot pedal before the carbs actually open up. If you pull back on #30, you will see how much play there is. There should be a slight amount of movement before the throttle shafts start to turn. What does your linkage look like? Rick |

| Rick Crawford |

| Hi Mike Rick and Doug are probably right about the linkage and what could be wrong, but it struck me that I had a similar symptom. When I first got my car it had a lot of play in the linkage - I initially assumed it was something wrong with the various levers and such, but with a bit of investigation I found that the two bushes in the firewall (number 19 on the diagram) were not there - presumably they broke and fell out. This made for a good half inch of slop, which looked like side to side play in the levers between the carbs. I initially tried to replace the bushes with the original parts, and after exhausting my supply of expletives, I found a post about the problem on the internet somewhere, with a parts list to buy from McMaster Carr, so I now have self-lubricating bronze bushes which will probably outlast the car, installed in just a few minutes. If you think it is useful I will dig out the details. Cheers Alistair |

| A Hewitt |

| Good advice from the guys above. Here are two web sites you should have in your favorites. http://www.74tr6.com/ and his fix. http://www.74tr6.com/throttle.htm http://tr6.danielsonfamily.org/ http://tr6.danielsonfamily.org/AcceleratorShaft.htm http://tr6.danielsonfamily.org/ControlRod.htm |

| Joe S |

| Mike- If it hasn't been ever rebuilt Follow Alistair's and Joe's advice |

| DON KELLY |

| Thanks for all of the advice. I have actually already replaced the accelerator shaft bushings and rebuilt the control rod. Everything is nice and tight, except for the triangle bracket. I plan on taking it off to take a closer look. I'm guessing that either the bracket or the bolt is worn a bit. |

| MV Van Duzee |

| On mine, the hole in the triangular bracket had gotten oblong. So the challaenge was to find something to sleeve it with that had an OD not to big and would fit snuggly onto the bracket as qwell as fit snuggly over the shoulder bolt to take up the slack from 40 years of wear. That's what I did, sleeved it. Rob |

| rw loftus |

| So Rob what did you use for a sleeve and where did you get it? Rick |

| Rick Crawford |

| Sorry Rick, I honestly can't remember now, it was some years ago. It might have been as simple as using a couple of lock washers. The ID comes in all standard sizes, the OD is also standard sizes, but no more than 1/16" or 1/8" bigger than the ID, depending on the size. Just put them in a vice and tap the one side so it's now a flat washer with a split as opposed to a lock washer. If you do that and have a complete set of drills, you might be able to drill out the bracket just enough to press in a flatened lock washer with a vice. I might have done that with that bracket, but like I said, I can't remember. I do know I've done that on other things where there has been a hole that was worn too big. If you want to get a better fit on the bolt than what you are getting with a lock washer, put it in a vise and cut throught where the 2 ends come together then squeese it together, that will made the OD a bit smaller and fit the bolt tighter. Rob |

| rw loftus |

| I would just replace all the linkage if you can't get it right |

| DON KELLY |

This thread was discussed between 18/03/2013 and 21/03/2013

Triumph TR6 index